Leeds City Council is exploring the use of three new pothole filling technologies which could help improve the speed, quality, and cost-effectiveness of pothole repairs across the city.

The trials follow similar tests carried out last year and come after a recent report to the council’s infrastructure, investment, and inclusive growth scrutiny board on its highway maintenance strategy, where members welcomed a proactive approach to strengthening the city’s pothole repair capability.

The latest phase of testing comes after persistent rainfall throughout January and February left ground conditions heavily saturated and road surfaces far more vulnerable to sudden deterioration. As a result, the number of potholes reported across the city has risen significantly over recent weeks. In response, the council’s highways teams have deployed additional resources to manage the increased demand.

The exploration of the new technology is a part of efforts to modernise the city’s approach to road repairs and improve long-term efficiency. The three systems under test are at various stages of use and evaluation and may offer faster, more durable, and lower-carbon solutions.

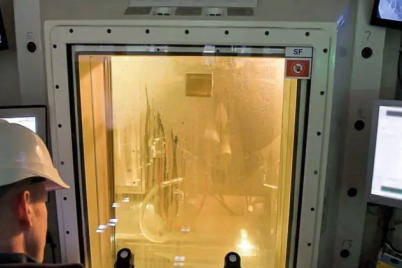

The first technology, which was tested in late 2025, was the Velocity pothole repair system. This high-speed spray injection method can repair potholes in under two minutes without excavation or waste. The process delivers an immediately traffic-ready, cost-effective and low-carbon repair.

More recently, the council has been utilising the JCB Pothole Pro following a short trial in July 2025. Mounted on a four-wheeled tractor unit, the machine uses a three-in-one tool system – planer, cropper and sweeper – to cut, clean and crop potholes, enabling a permanent repair in as little as eight minutes. The system also reduces the need for hand tools, minimises labour requirements and helps limit traffic disruption.

A third technology, known as thermal patching, will begin testing in spring 2026. This system uses infrared heat to warm existing asphalt and re-bond it with a minimal amount of new material. The result is a seamless, waterproof and jointless repair that significantly reduces carbon emissions, waste, and noise.

All three technologies and their respective benefits will be evaluated upon completion of their trials, after which the council will determine which, if any, should be adopted as part of the city’s long-term approach to road maintenance.

Leeds City Council’s executive member for economy, transport and sustainable development, Councillor Jonathan Pryor, said: “We recognise that potholes are a major issue in Leeds, and we understand the inconvenience, disruption and frustration they cause for individuals and communities.

“That is why we already afford a high priority to highway maintenance work, investing multi-million pounds each year via the council’s capital programme to this work.

“To complement this investment, we are carrying out trials of innovative technologies that have the potential to not only help tackle the backlog of existing road defects but also support our response to new issues created by the forty days of continuous rain we experienced in January and February this year.

“Having already seen one of these solutions operating with impressive results, I am confident that technologies like the three we are testing can help speed up and strengthen our response to road defects, while also offering cost-effective and efficient ways to keep our city moving.”